A Triple Offset Butterfly Valve Manufacturing and Their Impact on Industry

Triple Offset Butterfly Valves TOBVs are a sophisticated type of valve designed for high-performance applications requiring precise control and reliable operation. Unlike traditional butterfly valves, the triple offset design incorporates three key features that enhance its functionality and durability. The primary characteristic of a TOBV is its conical, or offset, disc seat which is positioned away from the valve body. This offset design ensures that the sealing surfaces are not in contact during the rotation of the valve, thus reducing wear and tear and increasing the valve’s lifespan. The triple offset design refers to three specific offsets: the first is the axial offset, where the axis of the disc is offset from the axis of the seat; the second is the angular offset, where the seat and disc cone surfaces are inclined to each other; and the third is the radial offset, where the axis of the disc is positioned away from the center of the valve body. These offsets create a camming action during valve operation, which significantly reduces friction between the disc and the seat. This unique design feature also ensures a tighter seal and minimizes leakage, making TOBVs suitable for high-pressure and high-temperature applications.

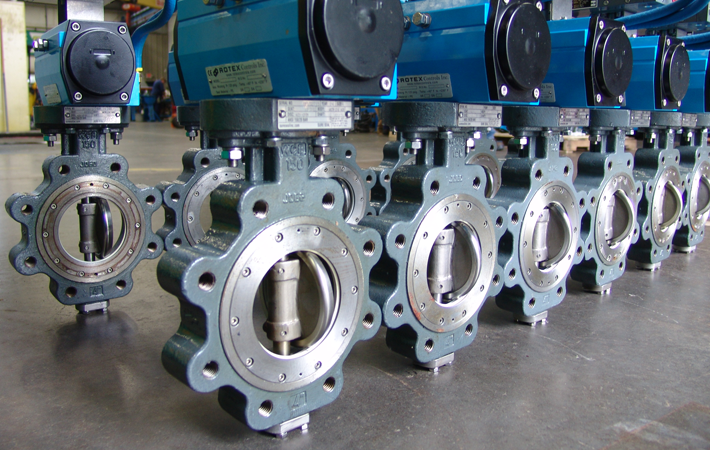

The process of triple offset butterfly valve manufacturers involves several critical steps to ensure their performance and reliability. Initially, high-quality materials such as stainless steel or nickel alloys are selected to withstand extreme conditions. The components are then precision-machined to exact specifications, including the disc, seat, and body. Advanced technologies, such as computer numerical control CNC machining and laser welding, are often employed to achieve the necessary precision and durability. The final assembly involves careful alignment and testing to ensure that the valve meets the required standards for leak-tightness and operational efficiency. The impact of triple offset butterfly valves on various industries is profound. In the oil and gas sector, they are used in critical applications such as pipeline isolation and flow control, where their ability to handle high pressures and temperatures is essential. Their robust design also makes them suitable for use in the chemical and petrochemical industries, where they can manage corrosive and abrasive fluids with ease.

Additionally, the power generation industry benefits from TOBVs due to their reliability and low maintenance requirements, which are crucial for maintaining the efficiency of power plants. Moreover, Dombor contribute to improved safety and environmental protection. Their tight sealing capability helps prevent leaks of hazardous substances, reducing the risk of environmental contamination and ensuring compliance with stringent regulatory standards. The reduced friction and wear also lower the likelihood of valve failure, contributing to overall operational safety and reducing downtime. In summary, triple offset butterfly valves represent a significant advancement in valve technology, combining innovative design features with advanced manufacturing techniques to deliver superior performance and reliability. Their impact across various industries underscores their importance in managing complex fluid control applications, offering enhanced safety, durability, and efficiency. As industries continue to evolve and face new challenges, the role of TOBVs in ensuring optimal performance and safety remains pivotal.